Lödige mixing systems for the food industry

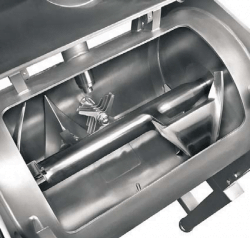

Lödige systems offer the required mixing and process precision for an ideal process design in a wide production range. Lödige systems and solution concepts are used worldwide, based on decades of practical experience in the construction of mixers and treatment systems for food producers. It goes without saying that Lödige provides a “Hygienic Design” and also implements extensive cleaning systems. Lödige mixers can be WIP/CIP-adapted and can then provide the greatest possible hygiene standards even for microbiologically critical components.

The cleaning of machines is indeed becoming more and more important. In the food industry an integrated cleaning system is now one of the basic requirements of a new machine. CIP or WIP systems are designed to prevent cross-contamination of allergens during product changes and potential microbiological contamination.

Lödige mixing systems can be designed and used for numerous products and production steps in the food industry. For instance, in addition to the conventional mixing step, it is possible to combine additional process steps in one Lödige system. This can make, for example, work-intensive pre-mixing unnecessary.

The advantages of Lödige systems for the food industry are manifold:

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- Maximum flexibility

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

For more information on the different Lödige mixing systems can be found though these links:

- Discontinuous mixing and granulation in a horizontal Lödige system

- Continuous mixing and granulation in a horizontal system

- Discontinuous mixing and granulation in a vertical Lödige system

- Mixing and processing in a continuous ring layer system

- Drying and mixing in a vacuum shovel dryer