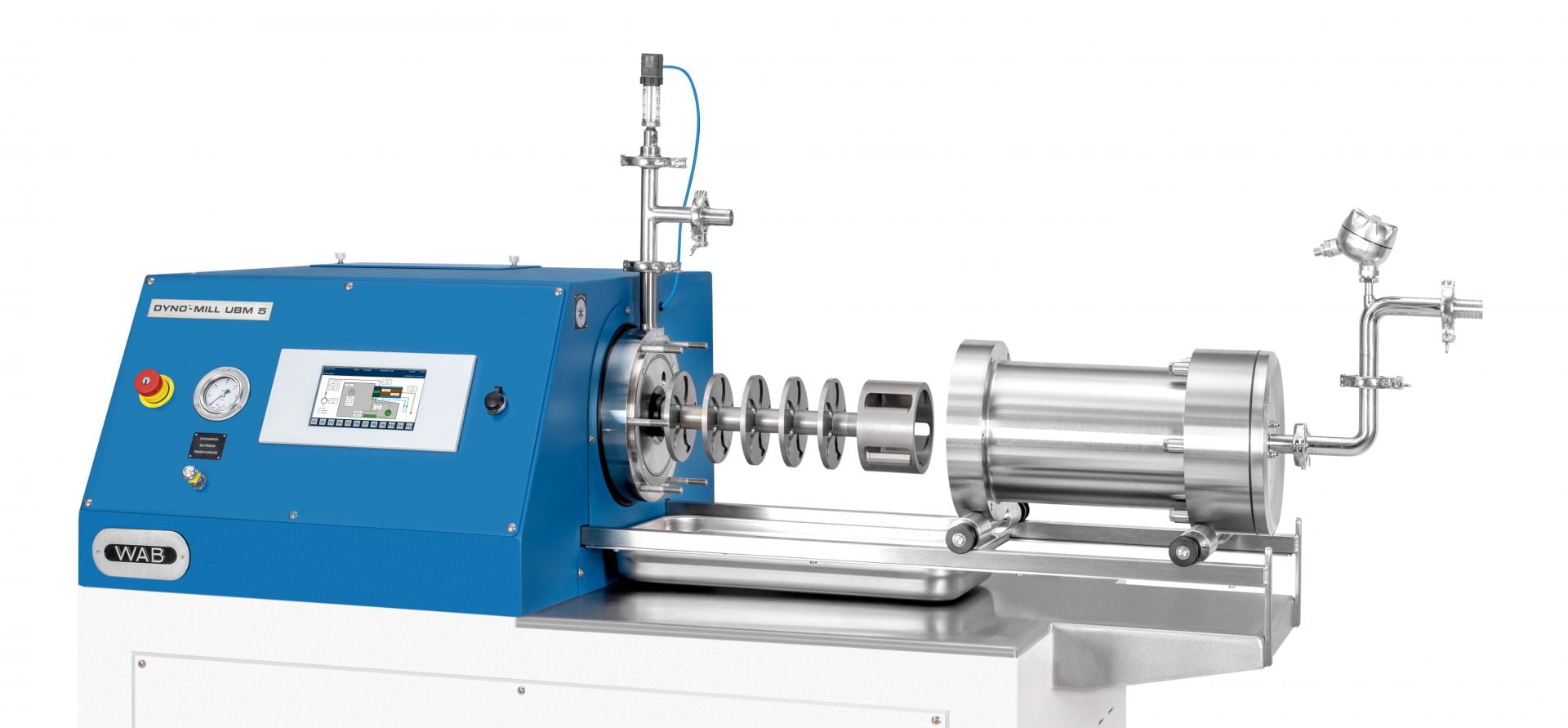

DYNO®-MILL UBM 5 : The new bead mill of the WAB-group

The WAB-group is expanding the range of DYNO®-MILL UBM bead mills with a machine for smaller production volumes: the DYNO®-MILL UBM 5

In addition to the laboratory mill, which was launched in 2019 under the name DYNO®-MILL Unilab, the range of DYNO®-MILL UBM production machines now consists of four machines: the UBM 5, the UBM20, the UBM50 and the UBM100.

It is clear that the machine manufacturer Willy A. Bachofen is continuing to focus on replacing the many old DYNO-MILL KD mills that are scattered all over the world. These machines are often 40 years and older, sometimes they still have a lip seal, but in any case they are less efficient than the new generation DYNO®-MILL UBM mills.

The innovative DYNO®-DISC BC grinding discs of this latest generation of bead mills keep the grinding beads in more or less closed compartments and enables them to act very efficiently on the product to be dispersed. As a result, we achieve a greater flow with smaller grinding chambers which makes the DYNO®-MILL UBM mills very energy-efficient.

Do your consider replacing your old machines, or are you looking for an efficient expansion of your production? Please contact Eskens Process Solutions via info@eskens.com, and we will arrange a comparative test for you on one of the DYNO®-MILL UBM mills.