DYNO®-MILL Agitator Bead Mills and Grinding Beads

Eskens Process Solutions has been selling, installing and servicing the DYNO®-MILL bead mills of the Swiss manufacturer Willy A. Bachofen (WAB) for more than 45 years. Our experienced specialists advise our customers in optimizing their grinding process. With our local stock of spare parts, we assure you a fast and efficient service. The DYNO®-MILL bead mills are used in the paint, ink and coating industry, as well as in the chemical, pharmaceutical, cosmetic and food industry.

DYNO®-MILL KD Agitator Bead Mills

- Since the nineteensixties, the DYNO®-MILL KD bead mills have been successfully used for grinding products in the production of paint, agrochemical and pharmaceutical products.

- De DYNO®-MILL KD mills are equiped with grinding discs in different designs, and are available with a grinding chamber from 6 to 600 liters. This makes them very versatile, even for difficult processes.

- De DYNO®-MILL KD agitator bead mills are easy to clean and can (with the necessary options) even be used for sterile production processes.

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

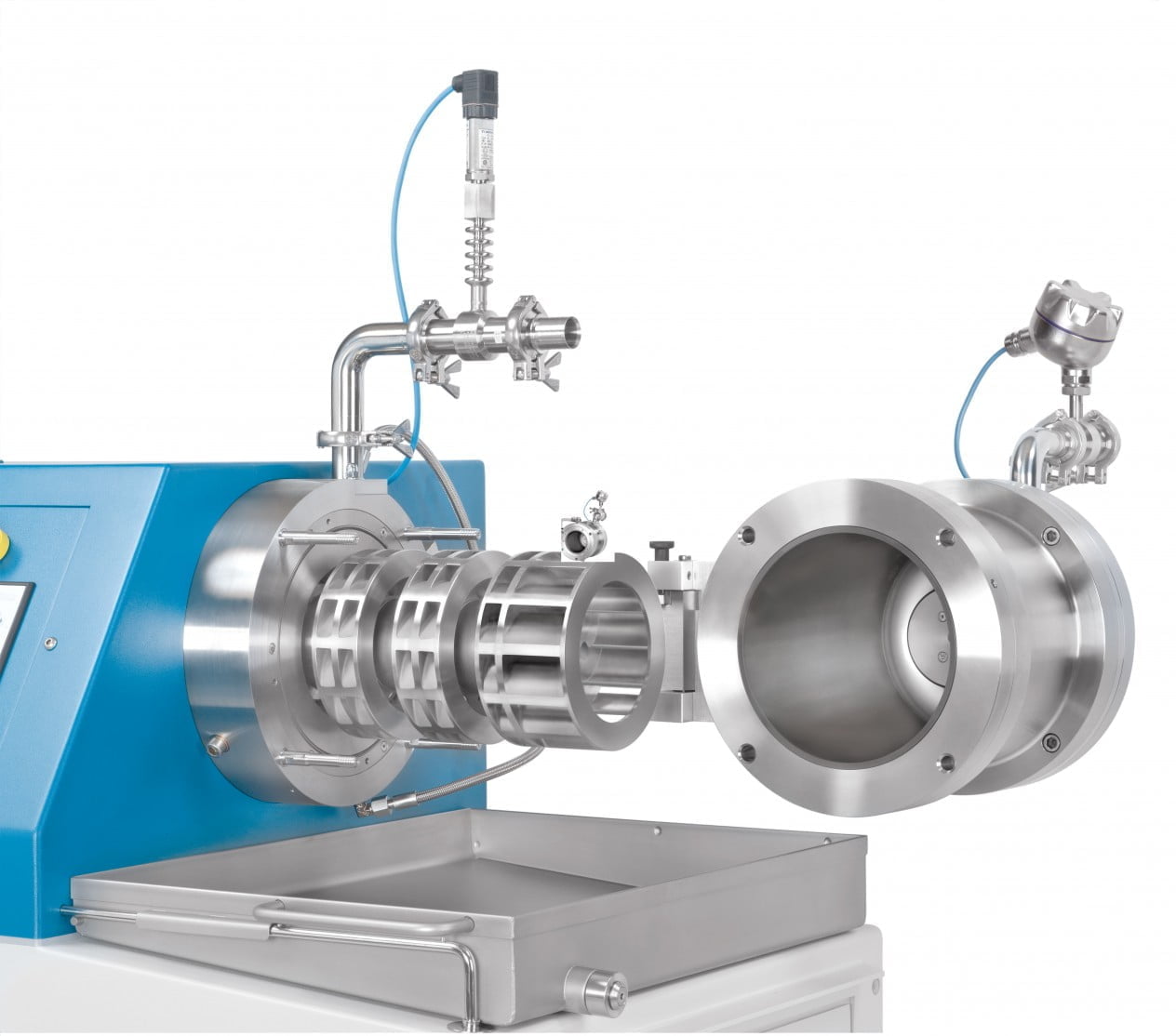

DYNO®-MILL UBM agitator bead mills

- The DYNO®-MILL UBM is a highly efficient bead mill due to the revolutionary DYNO®-DISC BC discs.

- These DYNO®-DISC BC discs divide the grinding chamber into separate compartments in which the grinding beads have an optimal impact on the product to be dispersed.

- The DYNO®-MILL UBM can treat very large volumes of product with relatively small grinding chambers.

- The DYNO®-MILL UBM bead mills can de-agglomerate and grind with beads from 0.2 to 2.5 mm.

- They are suitable for grinding processes in recirculation and in passage mode.

- These agitator bead mills have a grinding chamber of 5 lt. , 20 lt. , 50 lt. and 100 lt.

Would you like to do a test, or do you need some advice on the right machine to choose?

Then pleace send a mail to info@eskens.com

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

DYNO®-MILL ECM AP high efficiency agitator bead mills

- The DYNO®-MILL ECM AP bead mills put a lot of energy into the product.

- They are used for the de-agglomeration of products that are difficult to grind.

- The DYNO®-MILL ECM AP bead mills can de-agglomerate and grind down to the Nano range.

- Even highly viscous or foaming products can be de-agglomerated without any problems.

- Due to the combination of revolutionary accelerators and an extremely efficient final sieve, a high throughput can be achieved.

- These agitator bead mills can work in recirculation and in passage mode.

- The DYNO®-MILL ECM AP grinders have a small grinding chamber and are therefore easy to clean.

Would you like to do a test, or do you need some advice on the right machine to choose?

Then pleace send a mail to info@eskens.com

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

DYNO®-MILL ECM AP05 and DYNO®-MILL UniLab laboratory mills

- Both models are developed to be used for testing dispersions in the laboratory.

- The DYNO®-MILL ECM AP05 works with DYNO®-MILL accelerators, providing scalable results for the DYNO®-MILL ECM-AP bead mills.

- The DYNO®-MILL UniLab works with the DYNO®-DISC BC discs, delivering scalable results for the DYNO®-MILL UBM production machines.

- Both agitator bead mills are ideal for product development and small pilot plant productions.

- The results are 100% scalable.

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

DYNO®-MILL Research Lab maalmachine

- A multifunctional grinder for the laboratory.

- working with only one DYNO®-MILL accelerator.

- This mill is intended for product development with very small volumes (min. Batch volume is 100 ml).

- Ideal for feasibility studies, but does not provide scalable results.

- Comes with a 250 or 500 ml hopper.

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

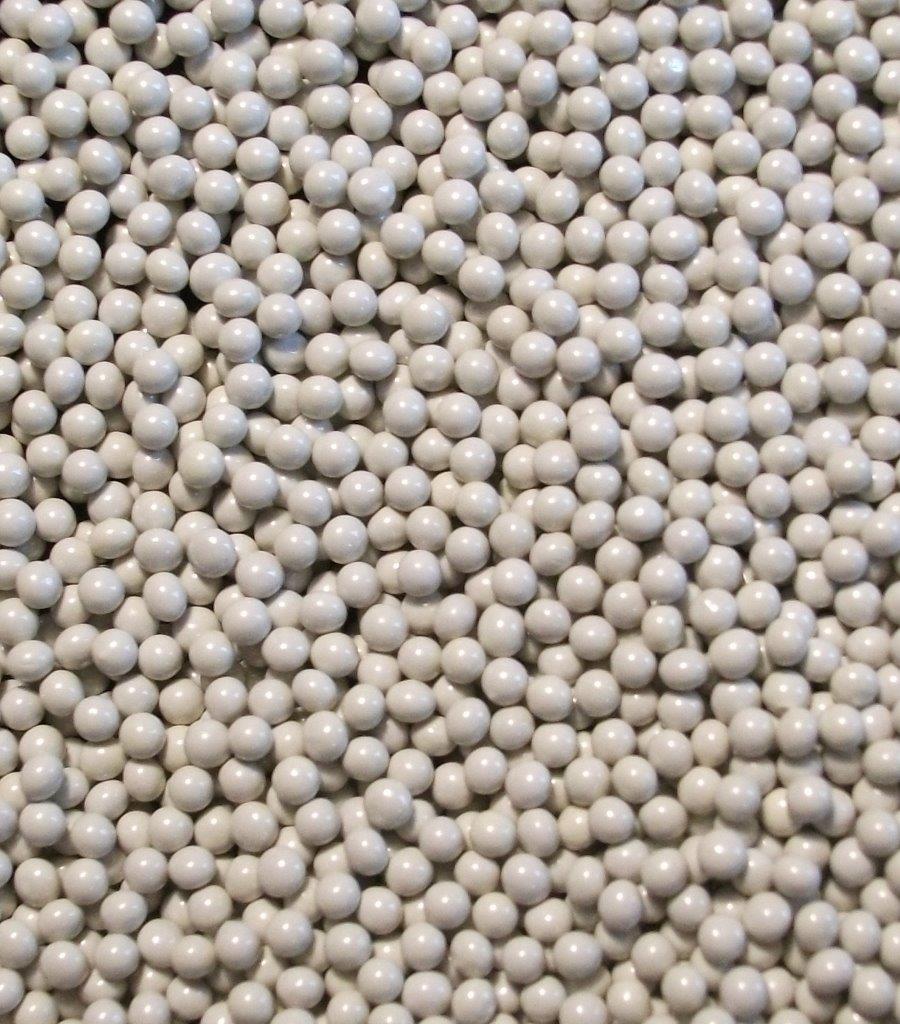

TOSOH ceramic grinding beads

- Tosoh grinding beads are made from Yttrium-stabilized zirconium (95% ZrO2, 5% Y2O3).

- They have a density of 3.8 kg/lt.

- These heavy beads generate a high impact force, resulting in superior grinding efficiency.

- The smooth surface and perfect roundness result in higher productivity in grinding and dispersing.

- Tosoh beads are made of very pure materials and have a very high wear resistance.

- As a result, Tosoh beads can be used for grinding ingredients for the food and pharmaceutical industry (certificates are available).

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

ZIRCONOX ceramic grinding beads

- Zirconox grinding beads are made of cerium stabilized zirconium oxide (Zr02 83%, CeO2 17%).

- They have a packing density of 3.75 to 4.05 kg/lt, depending on the bead size.

- The consistent microstructure of the Zirconox beads improves their hardness and toughness, resulting in a longer life and a more efficient milling process.

- Zirconox beads last over 300 times longer than glass beads and 6-8 times longer than zirconium silicate beads.

- The higher density of the Zirconox beads leads to higher milling efficiency, shorter processing times, higher throughput and the ability to process high-viscosity formulations.

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

ZIRCOSIL silicate grinding beads

- Zircosil grinding beads are made of zirconium silicate (ZrSiO4).

- They have a density of 2.6 kg/lt.

- Since Zircosil beads have a higher density than glass beads, they are ideally suited for the rapid dispersion and milling in horizontal bead mills.

- The smooth and shiny surface of the Zircosil beads reduces the wear and tear of the mill.

Send us an e-mail for more information

or call +31 172 468046

of bel (BE) +32 15 45 15 00

Our other products for Processing liquids

How can we help you?

We will reply immediately: info@eskens.com.

Or call us: +31 172 46 80 36 (Netherlands) or +32 15 45 15 00 (Belgium and Luxembourg).