DYNO®-MILL bead mills and grinding beads

For more than 40 years now, Eskens Process Solutions has been selling, installing and servicing the DYNO®-MILL grinding mills of the Swiss manufacturer Willy A. Bachofen (WAB). With our local stock of spare parts, we ensure you of rapid and efficient service.

The DYNO®-MILL grinding mills are used in the paint, ink and coating industry, as well as in the chemical, pharmaceutical, cosmetic and foodstuffs industry.

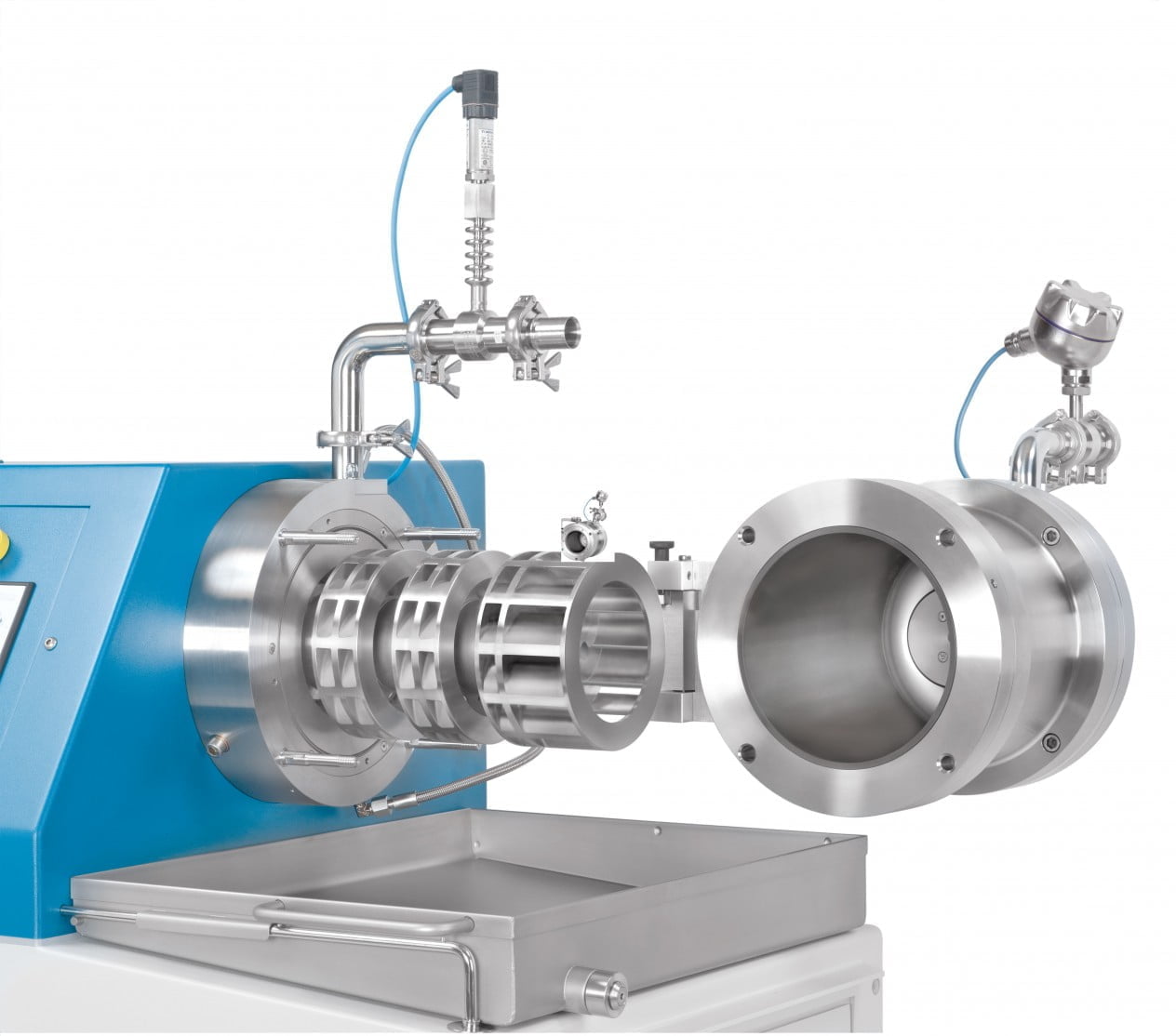

DYNO®-MILL KD grinding mills

More than 8,000 users are very satisfied with their DYNO®-MILL KD grinding mills. These highly reliable machines are used in the production of paint, coatings, agro chemistry and pharmaceutical products.

With a grinding chamber from 6 to 600 litres and their various systems to separate the pearls and the product, they can be used for a broad range of applications.

The DYNO®-MILL KD grinding mills can be modified for sterile production processes.

Send us an e-mail for more information

or call +31 172 468046 / +32 15 451500

DYNO®-MILL UBM grinding mills

- A new type of universal bead mills with DYNO®-DISC BC grinding discs and a unique end sieve can process very large volumes with relatively small grinding chambers.

- The DYNO®-MILL UBM grinding mills can grind with beads from 0.3 to 2.5 mm

- Ideal for very fine grinding of large volumes of product.

- Suitable for grinding in recirculation and in passage mode

Send us an e-mail for more information

or call +31 172 468046 / +32 15 451500

DYNO®-MILL ECM AP grinding mills

- Highly efficient and energy-efficient grinding mills

- Are used to disperse or to achieve ultra-fine wet grinding

- Can grind down to the Nano-range

- Highly viscous or foaming products can also be grinded problem-free

- The combination of revolutionary accelerators and a highly efficient end sieve enables very large volumes to be processed despite relatively small grinding chambers.

- Suitable for grinding in recirculation and in passage mode.

- They are very easy to clean

- Consume little energy.

Would you like test the mill? Or would you like advice on choosing the right machine?

If so, send an e-mail to: info@eskens.com

Send us an e-mail for more information

or call +31 172 468046 / +32 15 451500

DYNO®-MILL ECM AP05 laboratory mill

- highly energetic bead mills with DYNO®-MILL accelerators

- grinding down to the Nano-range

- ideal for product development and small pilot plant productions.

- 100% scalable results

Willy A. Bachofen AG also produces smaller lab mills, such as the highly compact DYNO®-MILL Research Lab, that can process a batch of as little as 120 ml with a 75 ml grinding chamber.

Send us an e-mail for more information

or call +31 172 468046 / +32 15 451500

DYNO®-MILL RL laboratory mill

- A multifunctional grinder for the laboratory

- working with only one DYNO®-MILL accelerator

- This mill is intended for product development with very small volumes (min. Batch volume is 100 ml)

- Ideal for feasibility studies, but does not provide scalable results

- Comes with a 250 or 500 ml hopper.

Send us an e-mail for more information

or call +31 172 468046 / +32 15 45 15 00

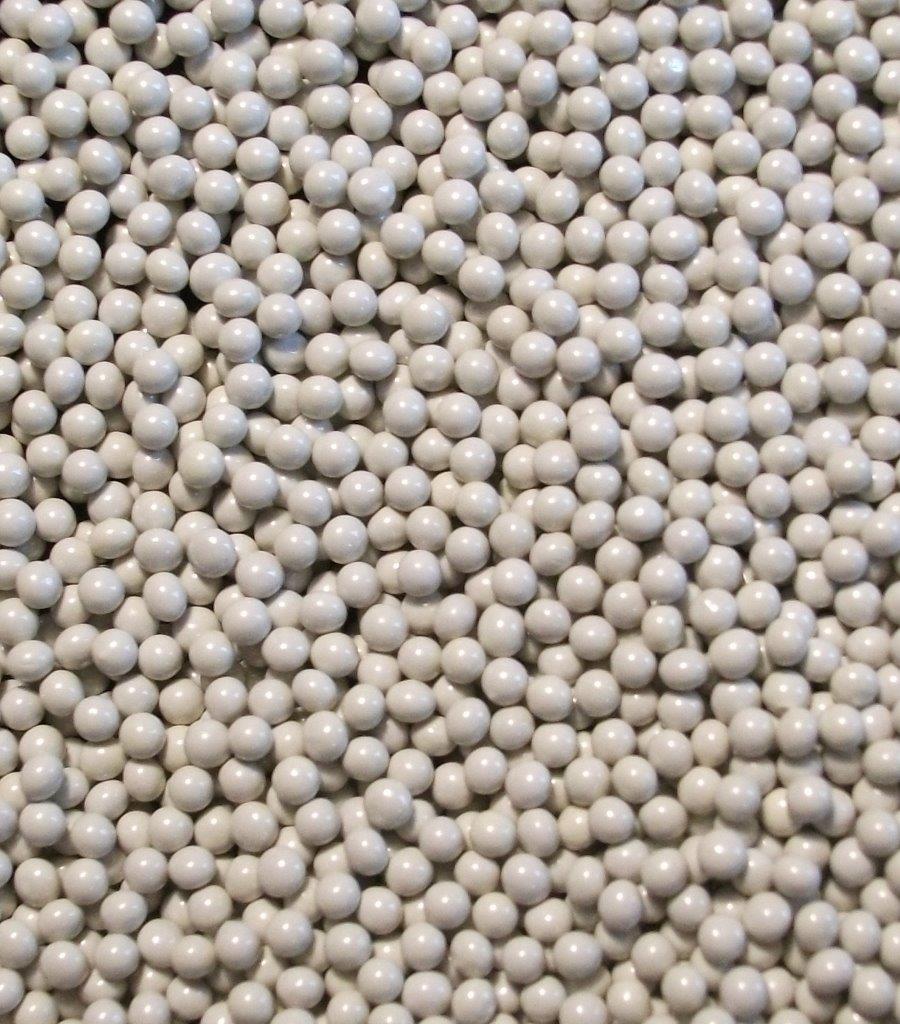

TOSOH Ceramic Beads

- Tosoh milling beads are made of Yttrium stabilized zirconium (95% ZrO2, 5% Y2O3)

- They have a packing density of 3,8 kg/lt

- This high density provides a greater impact force resulting in superior grinding efficiency.

- The smooth surface, and the almost perfect roundness and narrow size distribution, result in a higher productivity grinding and dispersion.

- Tosoh beads are produced from high purity materials, and have a very high wear resistance which results in minimizing product contamination from media wear.

- Tosoh ceramic beads can be used for foof and pharmaceutical applications (certificates are available)

Send us an e-mail for more information

or call +31 172 468046 / +32 15 45 15 00

ZIRCONOX Ceramic Beads

- Zirconox milling beads are made of cerium stabilised zirconium oxyde (Zr02 83%, CeO2 17%)

- They have a packing density of 3,75 to 4,05 kg/lt depending on the bead size

- The consistent microstructure of the Zirconox bead composition improves the hardness and toughness, resulting in longer bead life and lesser mill down time due to elimination of broken beads.

- Zirconox beads last over 300 times longer than the glass beads, and 6-8 times than the Zirconium Silicate beads.

- The higher density of Zirconox beads leads to increased milling efficiency, reduced processing time, higher throughputs and ability of processing higher viscous formulations.

Send us an e-mail for more information

or call +31 172 468046 / +32 15 45 15 00

ZIRCOSIL Ceramic Beads

- Zircosil milling beads are made of zirconium silicate ( ZrSiO4 )

- They have a packing density of 2,6 kg/lt

- Since Zircosil beads are of higher density than the glass and many ceramic beads, they are ideally suited for speedy dispersion / milling of hard and soft substances in horizontal bead mills

- The smooth and glossy surface of the Zircosil beads will considerably enhance the bead life and reduce on wear of the mill and its expensive parts.

- Zircosil beads have superior impact resistance due to their uniform and dense internal microstructure.

Send us an e-mail for more information

or call +31 172 468046 / +32 15 45 15 00

Our other products for Processing liquids

How can we help you?

We will reply immediately: info@eskens.com.

Or call us: +31 172 46 80 36 (Netherlands) or +32 15 45 15 00 (Belgium and Luxembourg).